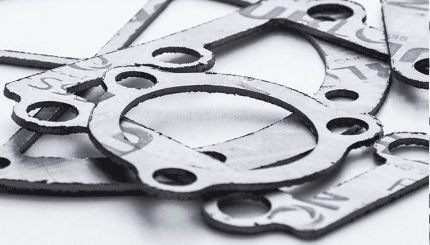

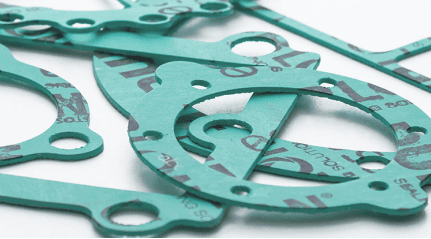

Gasket Materials from Durlon® Sealing Solutions

Effective fluid sealing solutions start with selection of the best possible gasket materials. With over a century of fluid sealing experience the Mercer Gasket & Shim Co. customer support staff possess the know-how to provide the best material for your sealing requirements. Mercer is an authorized stocking distributor offering a wide range of safe, reliable, and innovative gasket materials from Durlon® Sealing Solutions. The Durlon® time-tested materials are used to satisfy rigorous applications under the most demanding conditions in the chemical processing, paper & pulp, power generation, water & wastewater, rail-tank car, and pharmaceutical industries. Contact our support team with your gasket material needs!

Providing Innovative & High-Quality Fluid Sealing Solutions

- Compressed Non-Asbestos Sheets

- PTFE Sheets/Gaskets

- High Temperature Sheets/Gaskets

- Low Seating Stress Gaskets

- Water /Sanitation NSF/ ANSI 61 Gaskets

- Semi Metallic Gaskets

- Flexible Graphite Sheets/Gaskets

- Metallic Gaskets

Durlon® 9600 Expanded PTFE

- Made from pure PTFE resin that offers compressibility up to 60% and is resistant to highly aggressive chemicals

- Suitable for use in steel flanges and flanges with irregular surfaces

- Unique expanding process creates a high degree of fibrillation with nearly uniform strength in all directions minimizing cold flow and creep while maximizing performance stability and reliability

- FDA compliant, ABS-POA & USP Class VI certified

Durlon® HT1000 (Ultimate Mica Technology)

- Phlogopite mica paper impregnated with an inorganic binder

- Superior weight retention: less than 4% weight loss at 800°C [1,472°f), and extreme temperature sealing performance up to 1,000°C (1,832°f)

- Flexible, elastic, has a high tensile strength, can withstand substantial mechanical pressure perpendicular to the lamellar plane, chemically resistant fireproof, infusible, incombustible, and is a known non-toxic alternative to asbestos

- Available styles: S90, L316, T316

Durlon® Flexible Graphite

- Available in a homogeneous, laminated and tanged styles with various thickness stainless cores

- Unaffected by heat over a wide range of temperatures

- Exhibits low electrical resistivity and high thermal conductivity and is suitable for cryogenic temperatures

- FGS95: Standard industrial grade sheet containing no binders or resins

- FGL316: Standard industrial grade sheet laminated with an adhesive bond on both sides of a 0.002″ thick 316 stainless steel foil core

- FGT316. Standard industrial grade sheet mechanically bonded on both sides of a 0.004″ thick 316 stainless steel tang core.

- FGM316: Inhibited grade sheet laminated with multiple layers of 0.004″ thick 316 stainless steel toil core.

Durlon® 9000 Step Ring Gaskets

Gasket Resources Inc. has improved upon the original design of the “glued” Step Ring Gasket that has been the industry standard for years. The old design Step Ring Gasket consisted of a 1/16″ thick standard ring section plus a 1/16” thick inner ring section bonded together with an adhesive.

GRI is able to CNC machine Step Ring Gaskets out of a single piece of Durlon® 9000, all while maintaining the same dimensional design. The solid piece construction prevents the possibility of gasket separation and the unneeded maintenance cost of gasket material ending up in your process. Our easy to install Durlon” 9000 Step Ring Gaskets are great for low bolt load applications and raised face flanges that easily deflect.

Durlon® Sealing Products:

Safe, Reliable & Versatile

- Widest possible range of service applications – number of different types of gaskets to be inventoried can be greatly reduced

- Boost to process safety – limiting the number of gasket styles reduces the chance of installing the wrong gasket in the wrong service

- Unvarying performance on the job – gasket materials are manufactured to ISO 9001 :2015 quality standards and are subjected to continuous testing and rigid quality control

Durlon® 8700 Aramid/lnorganic/CR

- Contains high strength aramId and inorganic fibres bonded with high grade neoprene {CR) rubber

- Excellent resistance to ozone, Oils, non-aromatic solvents and refrigerants

- Top performer for original style HVAC OEM applications

Durlon® 8900

- Premium grade compressed high temperature non-asbestos sheet for service conditions to 496°C (925°f) and continuous operating temperatures of -73°C to 400°C ( 100°f to 752°f) or 13 8 MPa (2,000 psi)

- Passed ANSI/API 607 (6th Edition) Fire Test with zero recorded leakage

Durlon® 9000/9000N lnorganic/PTFE

- Durlon® 9000/9000N is for use in process piping and equipment in chemical, pulp & paper, food & beverage, pharmaceutical and other general industrial applications where resistance to highly aggressive chemicals is required and the shape of the fillers do not allow wicking which can cause corrosion on flange surfaces

- Durian 9000 has achieved numerous certifications: WRAS (Water Regulation Advisory Scheme) Approved Material, USP Class VI, FDA and (EC) 1935/2004 & EU (10/2011) BAM oxygen service, TA-luft (VDI Guideline 2440), ABS-PDA & Pamphlet 95, the chlorine institute, DNV-GL and has passed the API 6FA fire test

- Durlon® 9000N is FDA & USP Class VI certified

Durlon® 9002

- Meets extreme cryogenic demands

- Passed BAM certification for both gaseous and liquid oxygen tests up to 260°C (500°f) at 52 bar (754 psi)

- Traditional oxygen cleaning standards applied gaskets can be bagged, labeled and sealed according to the European Industrial Gases Association standard for Cleaning of Equipment for Oxygen service

- LOX Mechanical Impact Sensitivity (ASTM G86- 98a) passing with zero reactions out of twenty tests (0/20) at a test reaction frequency of 0%

- Conforms to FDA requirements of 21 CFR 1550 for food and drug

Durlon® 9200 Barium Sulfate/PTFE

- Barium sulfate filler blended with pure PTFE resin

- Suitable for hydrofluoric acid service

- BAM tested and certified for gaseous oxygen at pressures up to 52 bar (754 psi) and 260°C (500°f)

- Conforms to FDA requirements of 21 CFR 1550 for food and drug

Durlon® 9400 Carbon/PTFE

- Pure PTFE resin combined with carbon filler homogeneously dispersed throughout the compound

- Developed for use in general industrial applications where resistance to highly aggressive chemicals (Hydrofluoric Acid and Anhydrous Hydrogen Fluoride) is required

- Demonstrates good electrical conducting properties where flange electrical continuity is required

Durlon® 5000

- Good quality commercial grade compressed non-asbestos sheet tor moderate service conditions suitable for steam, oil, water, mild alkalis, mild acids, hydrocarbons and solvents

Durlon® 7900/7925/7950

- General purpose sheet containing high-strength aramid fibres bonded with high-grade (NBR) Nitrile Bonded Rubber

- For applications in steam, hydrocarbons and refrigerants and an alternative when temperature and pressure conditions are below 260°C (500°F) and 1200 psig

Durlon® 7910

- Commercial grade material containing high-strength aramid fibres bonded with high-grade (NBR) Nitrile Bonded Rubber

- Compressed sheet gasket material specifically developed to meet the requirement of NSF/ANSI 61 for potable water application at 23°C (73°F) to commercial hot 82°c (180°F)

Durlon® 8300 Carbon/NBR

- Premium grade, multi-service, high strength carbon fibre and NBR gasket sheet suitable for a broad range of chemical and thermal services

- Can be exposed to extreme pressures and temperatures

- Excellent sealability during thermal cycling

Durlon® 8400 Phenolic/NBR

- Outstanding material designed for higher temperature and pH applications

- Provides widest range of chemical resistance of any of our non-asbestos gasket material

- Excellent torque retention to maintain Cathodic Protection (CP)

Durlon® 8500 Aramid/Inorganic/NBR

- Contains blend of high strength aramid and inorganic fibres

- High performance gasket material for general purpose applications

- Surpassed the API 6FB fire test & conforms to FDA 21 CFR 1 n 2600

- HVAC service fitness tested and compatible with modem refrigerants

Durlon® 8600 Aramid/lnorganic/SBR

- Unique blend of high strength aramid and inorganic fibres with SBR binder for use in process industries including pulp & paper, power, petrochemical as well as general industry where a “white” gasket material is often required when working with food & beverage, pharmaceutical and plastics

Our Capabilities

Knife Cutting

Mercer Gasket & Shim’s highly accurate, state-of-the-art knife cutting capabilities allow us to deliver products to customers when speed, flexibility, and convenience are important.

Learn More Laser CuttingLaser Cutting

Specializing in fast turnaround of thin-gauge components, Mercer Gasket & Shim offers world-class laser cutting services for applications where precision is a high priority and quality is essential.

Learn More Waterjet CuttingWaterjet Cutting

Mercer Gasket & Shim’s waterjet cutting service offers a fast, flexible, and accurate method for fabricating complex or difficult parts while maintaining the integrity of the material.

Learn More Flatbed Die CuttingFlatbed Die Cutting

Our high-speed, Flatbed die-cutting can be used to create a variety of components, such as gaskets, packaging, bumpers, dampeners, labels, printed products, and more.

Learn More CNC Router CuttingCNC Router Cutting

Mercer Gasket & Shim is equipped with new, state-of-the-art router cutting equipment. We can assist with mid to high volume mass production runs.

Learn More