High Performance Fasteners for Demanding Applications

Leave a Comment Mercer Gasket & Shim, a trusted industry supplier for over a century, known for its expertise in gasket and small part manufacturing, is now an official distributor of LoneStar Group’s cutting-edge fastening products.

Mercer Gasket & Shim, a trusted industry supplier for over a century, known for its expertise in gasket and small part manufacturing, is now an official distributor of LoneStar Group’s cutting-edge fastening products.

The coupling of Mercer’s industry knowledge and LoneStar’s outstanding products ensures that domestically manufactured, high-performance, fasteners of uncompromising quality are available to our customers across a range of demanding process industries.

The coupling of Mercer’s industry knowledge and LoneStar’s outstanding products ensures that domestically manufactured, high-performance, fasteners of uncompromising quality are available to our customers across a range of demanding process industries.

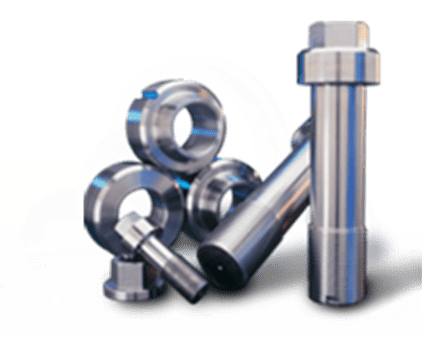

LoneStar Group is a globally recognized domestic manufacturer and supplier of high-performance fasteners. Whether you require off-the-shelf fastening components or specialized fasteners tailored to your unique specifications, Lonestar and Mercer Gasket & Shim have the combined expertise and resources to deliver. We offer a comprehensive range of standard and metric fasteners, such as bolts, double-end fasteners, tap end fasteners, and all-thread fasteners, all manufactured to meet SAE, ASTM, and ISO grade standards.

Lonestar can custom machine special fasteners, per print up to 32-inch diameters on items such as riser bolts, turbine bolts, stems, connector rods and collar studs. For uncompromising performance under the most demanding conditions such as extreme temperature and excessive wear, customers can chose from a number of coating and plating options. These fasteners are manufactured in accordance with ASTM.

Mercer Gasket & Shim serves industries such as oil and gas, petrochemical, power generation and other industries requiring fastening solutions capable of withstanding harsh and demanding conditions.

Both Mercer Gasket & Shim and Lonestar are ISO 9001:2015 registered, with exceptional quality control standards offering quick turn around and delivery for a broad and diverse range of standard and custom fasteners such as:

HEADED BOLTS

- Grade 5 Finished Hex Cap Screws

- Grade 8 Finished Hex Cap Screws

- Hex Head Lag Screws

- Carriage Bolts

- Square Head Machine Bolts

STUD BOLTS & NUTS

- A193 B7 All Thread/Double End Studs

- A193 B7M All Thread/Double End Studs

- A194 2H Heavy Hex Nuts

- Al94 Gr. 2HM Heavy Hex Nuts

- A320 L7 All Thread/Double End Studs

- A320 L7M All Thread/Double End Studs

- A194 Gr. 4 & 7 Heavy Hex Nuts

- A193 B 16 All Thread Studs

- A193 B8 All Thread Studs and Nuts

- A193 B7 Heavy Hex Bolts

NUTS

- Finished Hex Nuts

- Heavy Hex Nuts

- Hex Machine Screw Nuts

- Cap Nuts

- Coupling Nuts

- Wing Nuts

- Jam Nuts, Finished and Heavy

- Slotted Nuts and Castle Nuts

WASHERS

- USS Flat Washers

- SAE Rat Washers

- MS and AN Washers

- Fender Washers

- Split Lock Washers

- Tooth Lock Washers

- High Collar Lock Washers

- Bevel Washers

- Belleville Washers

STRUCTURAL BOLTS, NUTS & WASHERS

- A325 Heavy Hex Bolls

- A563 Grade Nuts

- A490 Heavy Hex Bolts

- A307B Heavy Hex Bolts

- F436 Hardened Structural Washers

- A325 Load Indicator Washers

- A325 Bevel Washers

- Socket Head Cap Screws

- Socket Set Screws

- Socket Shoulder Screws

- Socket Pipe Plugs

- Hex Keys

- Nylon Insert Locknuts

- Steel Locknuts

- Cotter Pins

- Dowel Pins

- U-Bolts – Special

- Eye Bolts – Special

- Hanger Bolts

- Blind Rivets

- Headless Sets

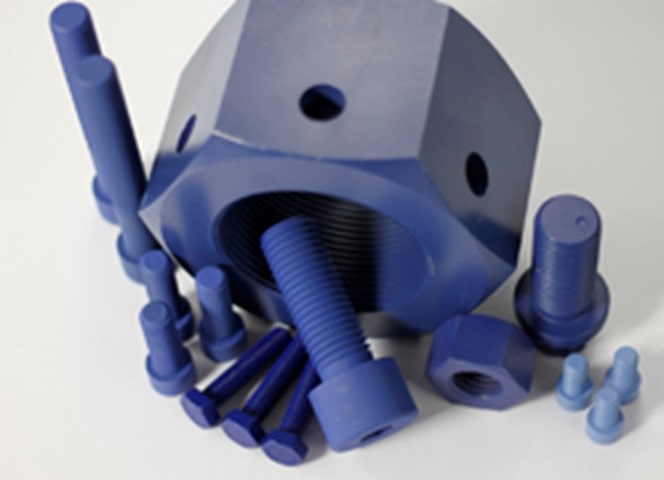

COATINGS

- Zinc Electro-Plating

- Xylan Coatings©

- PCl-3TM

- PCl-3+TM

- PCl-3+STM

- Sermagard Coatings

CAPACITY

- Forging – Nuts ¼” to 4”

- Forging – Bolts ¼” to 2”

- Roll Threading ¼” lo 4”

- Cut Threading ¼” to 4”

- Milling and Drilling

- CNC Laities to 32”

- Heat Treating – 10 tons/day

- Electroplating – 6 tons/day

- Fastener Coating – 10 tons/day

VALUE SERVICES

- Special Coatings

- Vendor Managed Inventory Program

- EDI & Internet Interface

- Quality & Testing Programs

FASTENER MATERIALS

- 304

- 316

- 321

- 347

- 410

- 416

- 422

- 501

- 904L

- 2205

- 2507

- 13-8PH

- 17-4PH

- A286/660

- NitronicTM 50 & 60

- MonelTM K-500

- lnconelTM 600 & 625

- Brass & Bronze

- Corbon & Alloy

- Others available on request

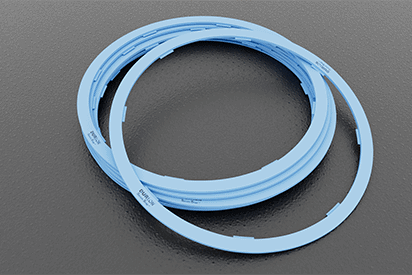

for NARs is heightened. The required tolerances for these conventional style gaskets are difficult to achieve and create quite a bit of scrap during the manufacturing process. In addition, if the ID is too small, installation becomes difficult if not impossible. On the other hand, if the ID is too large the gasket will easily fall out of the groove and into the manway nozzle. The result of this happening will cause leaks, splashes, and other releases from an improperly secured manway cover.

for NARs is heightened. The required tolerances for these conventional style gaskets are difficult to achieve and create quite a bit of scrap during the manufacturing process. In addition, if the ID is too small, installation becomes difficult if not impossible. On the other hand, if the ID is too large the gasket will easily fall out of the groove and into the manway nozzle. The result of this happening will cause leaks, splashes, and other releases from an improperly secured manway cover.