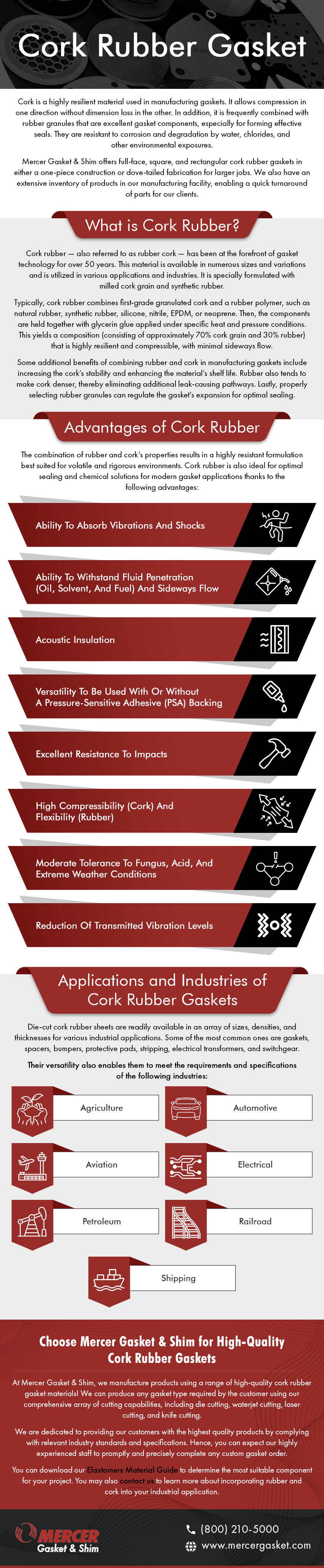

Cork is a highly resilient material used in manufacturing gaskets. It allows compression in one direction without dimension loss in the other. In addition, it is frequently combined with rubber granules that are excellent gasket components, especially for forming effective seals. They are resistant to corrosion and degradation by water, chlorides, and other environmental exposures.

Mercer Gasket & Shim offers full-face, square, and rectangular cork rubber gaskets in either a one-piece construction or dove-tailed fabrication for larger jobs. We also have an extensive inventory of products in our manufacturing facility, enabling a quick turnaround of parts for our clients.

What Is Cork Rubber?

Cork rubber — also referred to as rubber cork — has been at the forefront of gasket technology for over 50 years. This material is available in numerous sizes and variations and is utilized in various applications and industries. It is specially formulated with milled cork grain and synthetic rubber.

Typically, cork rubber combines first-grade granulated cork and a rubber polymer, such as natural rubber, synthetic rubber, silicone, nitrile, EPDM, or neoprene. Then, the components are held together with glycerin glue applied under specific heat and pressure conditions. This yields a composition (consisting of approximately 70% cork grain and 30% rubber) that is highly resilient and compressible, with minimal sideways flow.

Some additional benefits of combining rubber and cork in manufacturing gaskets include increasing the cork’s stability and enhancing the material’s shelf life. Rubber also tends to make cork denser, thereby eliminating additional leak-causing pathways. Lastly, properly selecting rubber granules can regulate the gasket’s expansion for optimal sealing.

Advantages of Cork Rubber

The combination of rubber and cork’s properties results in a highly resistant formulation best suited for volatile and rigorous environments. Cork rubber is also ideal for optimal sealing and chemical solutions for modern gasket applications thanks to the following advantages:

- Ability to absorb vibrations and shocks

- Ability to withstand fluid penetration (oil, solvent, and fuel) and sideways flow

- Acoustic insulation

- Versatility to be used with or without a pressure-sensitive adhesive (PSA) backing

- Excellent resistance to impacts

- High compressibility (cork) and flexibility (rubber)

- Moderate tolerance to fungus, acid, and extreme weather conditions

- Reduction of transmitted vibration levels

Applications and Industries of Cork Rubber Gaskets

Die-cut cork rubber sheets are readily available in an array of sizes, densities, and thicknesses for various industrial applications. Some of the most common ones are gaskets, spacers, bumpers, protective pads, stripping, electrical transformers, and switchgear.

Their versatility also enables them to meet the requirements and specifications of the following industries:

- Agriculture

- Automotive

- Aviation

- Electrical

- Petroleum

- Railroad

- Shipping

Choose Mercer Gasket & Shim for High-Quality Cork Rubber Gaskets

At Mercer Gasket & Shim, we manufacture products using a range of high-quality cork rubber gasket materials! We can produce any gasket type required by the customer using our comprehensive array of cutting capabilities, including die cutting, waterjet cutting, laser cutting, and knife cutting.

We are dedicated to providing our customers with the highest quality products by complying with relevant industry standards and specifications. Hence, you can expect our highly experienced staff to promptly and precisely complete any custom gasket order.

You can download our Elastomers Material Guide to determine the most suitable component for your project. You may also contact us to learn more about incorporating rubber and cork into your industrial application.